Optimal availability, productivity and the efficiency of

company processes go to form an effective maintenance system, and are crucial to a company’s success.

If repairs only occur once a production system is at a standstill,

considerable costs are often the result. We help you to avoid downtime

and react before technical problems appear in your machinery. In order to guarantee this,

we have developed a proactive maintenance concept for the sustainable optimisation of your systems, machines and processes.

Our TSA service: repair, maintenance, analysis and optimisation of your systems

with intelligent spare parts management and 24/7 availability.

Periods of downtime cause annoyance in the company, along with unnecessary, and often high, costs.

Our maintenance service helps you to keep both as low as possible.

We understand maintenance as being a systematic process of maintaining and documenting systems and components with the focus being on improvement. This guarantees, or even improves, their functioning.

The breakdown of individual assemblies can result in enormous damage to the entire production system. Damage is only recognised once it occurs.

By deploying suitable monitoring and diagnosis systems, which measure and interpret defined parameters, it is possible to inform you about deviations from the performance required and about potential system faults, thus avoiding failures further down the line.

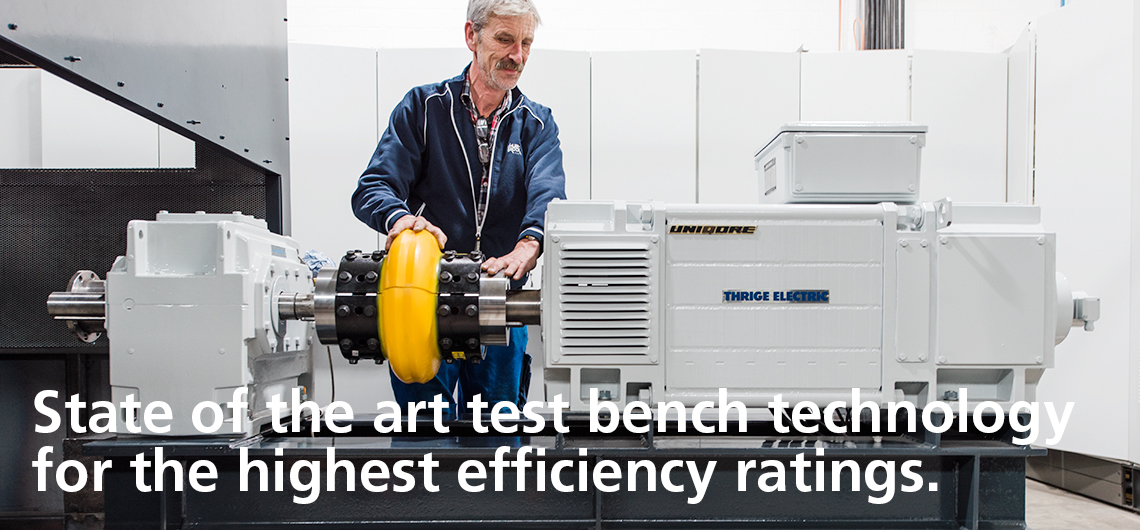

These days, maintenance and repair is simply not possible without automated test systems. Using state of the art test bench technology, we undertake reliable and reproducible measurements in order to test the performance of the motors and drives we overhaul. This includes tests to ensure that parameters are adhered to, tests to classify efficiency, as well as many other tests.

With the aid of optimized control and feedback control systems such as frequency converters, we are able to optimize the efficiency of the systems further and achieve the highest potential for savings. We support you from conception and analysis, the system’s project planning, creation of the circuit diagrams, switchgear construction and programming right up to construction, installation and commissioning.

When it comes to compressed air technology too, we can optimize your system in all aspects relating to performance, safety and efficiency. Whether generating, preparing or using compressed air, we ensure efficient and safe compressed air supply.

Irrespective of whether you want to plan a new project, extend or optimize. Together we will ensure that your compressed air system’s individual components are a perfect match for one another and that they are perfectly tailored to your individual requirements.

On the basis of the analyses that we carry out, along with grounded knowledge when it comes to system optimisation, we offer tailored solutions that will increase the cost-effectiveness, performance and reliability of your production systems.

Thanks to our tool and fixture construction facilities, along with our own data capture systems, we are able to adapt precisely to your requirements. Precision work of the very highest quality.Our long-term client base includes businesses from the mechanical engineering, special engineering, casting technology, automotive and chemical industries in Germany, France, Austria and Switzerland.

The trouble-free procurement of spare parts is essential for guaranteeing unbroken availability of your systems. In order that your systems can be up and running again after a breakdown, we are able to draw upon a comprehensive range of C-parts and special parts.

24/7 Service

Reliable machine availability

Reduces production downtime

Minimises maintenance costs

Increases production capacity and productivity

Saves energy costs

Reduces inventory holding costs